The manufacturing industry is under pressure like never before to increase efficiency, cut costs and improve quality. In order to meet these challenges, manufacturers are turning to digital transformation initiatives powered by the Internet of Things (IoT).

What is digital transformation?

In simple terms, digital transformation is the process of using technology to create new or improved business processes, products, or services. In manufacturing, digital transformation can be used to improve operations, increase efficiency, and reduce costs.

Why is digital transformation important in manufacturing?

The manufacturing industry is under pressure to improve operations and stay competitive. In the past, manufacturers have relied on manual processes and human labor to produce goods. However, this is no longer feasible in today’s global market.

With the advent of Industry 4.0, or the fourth industrial revolution, manufacturers must now rely on technology to improve operations and stay competitive. Industry 4.0 is the integration of cyber-physical systems, the Internet of Things, and advanced analytics. This new era of manufacturing requires manufacturers to be more agile, innovative, and customer-centric.

Digital transformation can help manufacturers become more agile and responsive to change. It can also help them be more innovative in their products and services. Additionally, digital transformation can help manufacturers better understand and serve their customers.

IoT-driven digital transformation can help manufacturers achieve their goals by providing real-time data and insights that can be used to improve processes and make better decisions. In this guide, we’ll explore how IoT is being used in manufacturing and some of the benefits that it can offer.

IoT in Manufacturing: The Benefits

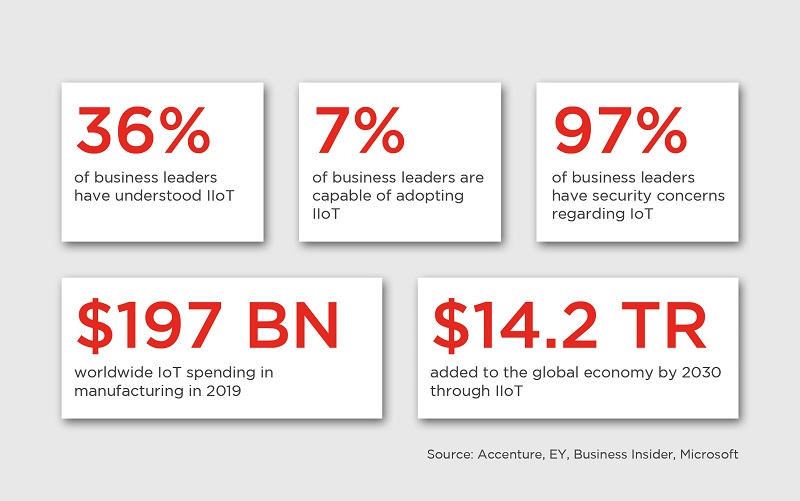

Sources: Accenture, EY, Business Insider, Microsoft

There are many potential benefits of using IoT in manufacturing, including:

1. Increased Efficiency

One of the main benefits of IoT in manufacturing is increased efficiency. By collecting data on how machines are operating, it’s possible to identify bottlenecks and areas for improvement. For example, if a machine is regularly stopping due to a lack of raw materials, this can be addressed by ensuring that the right materials are always available.

2. Improved Quality

Another benefit of IoT in manufacturing is improved quality. By monitoring machines and processes in real-time, it’s possible to identify issues early and take steps to prevent them from happening. This can result in a reduction in defects and an improvement in overall product quality.

3. Reduced Costs

IoT can also help manufacturers reduce costs. For example, by monitoring energy usage, it’s possible to identify opportunities for cost savings. Additionally, by using predictive maintenance, it’s possible to avoid costly downtime by fixing problems before they happen.

4. Improved Safety

Finally, IoT can also help improve safety in manufacturing settings. By collecting data on hazardous conditions, it’s possible to take steps to prevent accidents from happening. Additionally, by providing real-time visibility into dangerous areas, it’s possible to ensure that workers are always aware of potential hazards.

How IoT Is Being Used in Manufacturing

IoT is being used in manufacturing in a variety of different ways. Some common applications include:

1. Connected Machines

One of the most common ways that IoT is being used in manufacturing is by connecting machines. By attaching sensors to machines, it’s possible to collect data on how they’re being used and identify areas for improvement. Additionally, connected machines can be controlled remotely, which can lead to increased efficiency.

2. Predictive Maintenance

Another common application of IoT in manufacturing is predictive maintenance. By collecting data on how machines are being used, it’s possible to identify potential issues before they happen. This can help avoid downtime and keep production lines running smoothly.

3. Quality Control

IoT is also being used in manufacturing to improve quality control. By attaching sensors to products, it’s possible to track them throughout the production process and ensure that they meet quality standards. Additionally, by using IoT to monitor the production process, it’s possible to identify issues that could lead to defects.

4. Supply Chain Management

Finally, IoT is also being used to improve supply chain management. By tracking products throughout the supply chain, it’s possible to ensure that they’re always available when needed. Additionally, by using IoT to monitor the transport of goods, it’s possible to ensure that they arrive on time and in good condition.

5. Smart Packaging

In addition to the applications mentioned above, IoT is also being used in manufacturing to create smart packaging. By attaching sensors to products, it’s possible to track them after they’ve been shipped and ensure that they arrive safely at their destination. Additionally, by using smart packaging, it’s possible to provide customers with information about the product, such as how to use it or how to recycle it.

6. Factory Automation

One of the most exciting applications of IoT in manufacturing is factory automation. By using IoT to connect and control machines, it’s possible to create a fully automated production line. This can lead to increased efficiency and improved quality control. Additionally, by automating the production process, it’s possible to reduce the need for human workers, which can lead to cost savings.

The Future of IoT in Manufacturing

IoT is still in its early stages, but it’s already having a major impact on manufacturing. In the future, IoT is expected to become even more commonplace, with even more applications being developed. Some of the ways that IoT is expected to impact manufacturing in the future include:

The internet of things is transforming manufacturing. By connecting devices and machines to the internet, manufacturers can collect data, increase efficiency, and improve safety. IoT-driven digital transformation can help manufacturers reduce costs, improve quality, and speed up time to market. In addition, IoT can create new revenue streams and business models. The future of IoT in manufacturing is very exciting. With the right strategy and implementation, IoT can help manufacturers become more agile, adaptive, and competitive.

Microsoft tops the latest Forrester report, “The Forrester Wave™: Industrial IoT Software Platforms”. It shows Microsoft as a leader in IoT partner strategy, innovation roadmap, platform differentiation criteria, and market presence.

Sources: The Forrester Wave: Industrial IoT Software Platforms (Forrester)

According to Forrester’s report,

“Microsoft powers industrial partners but also delivers a credible platform of its own. Microsoft continues to add features to the platform at an impressive rate, with the richer edge capabilities of Azure IoT Edge and the simplified application and device onboarding offered by Azure IoT Central formally launching since we last evaluated this market.”

Microsoft will continue to defend its leadership position in IIoT with the continued development and implementation of AI, Edge Computing, and 5G technologies. The goal is to link IIoT workflows with data and processes across the enterprise, transform analysis into actionable information, and use that data to make decisions that strengthen the business in the long term.